The situation is getting worse in the maritime transportation market

Around the planet, the pandemic has disrupted trade to an extraordinary degree, driving up the cost of shipping goods and adding a fresh challenge to the global economic recovery. The virus has thrown off the choreography of moving cargo from one continent to another.

At the center of the storm is the shipping container, the workhorse of globalization.

UPDATE: 6/24/2021

The situation is getting worse in the maritime transportation market

Ports in southern China impacted by Covid-19 lockdowns (YANTIAN/ SHEKOU/HONG KONG/ NANSHA/HUANGPU) are further disrupting the global box trade and have seen a significant slump in container availability over the last two weeks.

It is estimated that more than 600,000 TEUs have been affected by the fallout from a Covid-19 epidemic around the port of Yantian in southern China.

Ports around the world are poised for a severe shortage of equipment in the weeks to come.

Ocean carriers are rolling out more rate increases next week, with FAK rates from Asia to North Europe edging towards $20,000 per 40ft.

This represents an incredible 1,000% increase on the spot rate compared to a year ago.

Meanwhile, transpacific carriers hit Asia to US shippers on June 15th, with GRI’s of up to $3,000 per 40ft, with some carriers now asking $17,000 per 40ft for US east coast ports.

Asia to North Europe rates climbed a further 5%, to around $16,000 per 40’ container.

The Yantian and other ports in South China lockdown will have a much larger impact on the flow of goods in the transpacific than the Suez Canal blockage.

Importers will be severely impacted as their containers sit in South China for weeks on end with little or no access to vessels.

And when the backlog in China eases, the pressure will still be on the US west coast ports.

The congestion at southern Californian ports had shifted from shipside to landside, specifically due to rail carriers being unable to clear the terminals' containers.

In a nutshell, here is what is at stake

further freight rate hikes are expected up to $ 20,000 / 40 ’on the Asia - Europe trade

The US market is also suffering from this rate hike with the addition of congestion that is spreading in the US inland. Transatlantic trade is suffering from this contagion and European exporters to the US are also seeing rates rise sharply

The main cause of these new increases is the Covid crisis, particularly in southern China, or in Yantian, for example, around 65 ships are waiting to dock.

The blocking of Yantian will probably have an even more serious impact on importers than the blocking of Suez.

Full containers are on hold for weeks at Yantian as there are few or no ships.

All shipping lines’ vessel schedules are irregular and change with no prior notice.

****

UPDATE: 6/14/2021

CLOSING OF YANTIAN PORT LEADS TO MASSIVE DELAYS

Disruptions in and around the key southern China container port of Yantian continue to worsen following the partial closure of the port in response to an outbreak of Covid-19 among terminal staff, with carriers announcing significant disruptions to sailings and schedules and warning of delays for at least 2 or 3 weeks.

The congestion at southern China’s biggest export container port has resulted in container lines blank sailings or bypassing Yantian and escalating congestion and restrictions at neighboring Shekou Port in Shenzhen and Nansha Port in Guangzhou.

The disruption in China will eventually spill over and disrupt European and North American markets again.

There is no spare capacity in North America or China to handle this level of disruption.

UPDATE June, 7th, 2021: The situation remains tense in the maritime transport market.

The sea freight rates are revised upwards by all carriers and the validity is reduced, a sign that the market is still tight and uncertain. Cargo ships are still close to filling rates up to 130% in some cases.

There are the same difficulties and the same level of tension as in the pre-Chinese New Year in terms of capacity, as demand is extremely high.

Blanks sailing programs are still on the agenda for the coming weeks for all alliances.

The situation will remain tight until the end of the 2nd quarter at least, with both import and export vessels being full for the next 4 to 6 weeks depending on the trade lanes.

- North China suffered the full brunt of blanks sailing with the discontinuance of certain services for 3 consecutive weeks.

In the ports of Dalian / Xingang / Qingdao: equipment is scarce and prices are soaring.

- Transshipment ports are extremely saturated, some operators apply FIFO in order to relieve congestion.

- The major Southern China base port of Yantian, located in Shenzhen, temporarily suspended operations due to the Covid-19 outbreak; the backlog of laden containers waiting to export has caused substantial congestion

- The situation in Los Angeles is still congested with 20 to 25 ships waiting in the bay.

- The LATAM market is the market that has suffered the most inflation in the price of the container.

- The price of fuel remains at a level of 500 USD per metric ton (VLSFO).

The spot rates recorded again rates in excess of USD 15,000 per 40’.

In general, shipping companies have drastically reduced allowances for a number of contracts, in order to favor spot rates.

***

UPDATE May, 17th, 2021:

Prices for sea container transport and air freight remain at high levels in an inflationary economic context. The health crisis has plunged the majority of industrialized countries into a major economic recession. A vigorous but asymmetrical recovery is emerging from the second quarter of 2021. The risk of inflationary pressures seems to be confirmed. The first indicators of an increase in the price of raw materials, energy, and freight rates are already present since the first quarter of 2021.

Economic recovery in V often generates a strong rate of growth in many economic sectors, but it also shows a risk of stock shortages and an upward trend in the price of inputs.

The economic statistics for March show strong growth in new manufacturing orders and an increase in export sales.

This growth in business is putting more pressure on supply chains and leading to increased lead times and shortages.

At the European level, data from purchasing managers show the largest increase in the price of purchases in ten years in the manufacturing sector and a steady decline in inventories for 26 months.

Manufacturers, therefore, tend to increase their selling prices to preserve their operating margin.

These are all parameters that affect the evolution of air transport and maritime transport prices.

AIR FREIGHT

The COVID-19 crisis has triggered severe volatility in the global air cargo industry on both supply and demand sides.

Since dedicated freighter charters and aircraft have made up for much of the capacity losses, freighters are now the backbone of the air cargo market.

However, with continued outbreaks and travel restrictions likely to remain in place, it is unclear how much belly capacity can – or will – be added throughout 2021 as countries struggle to curb the impact of the COVID-19 pandemic.

SEA FREIGHT

Containerized maritime transport: high prices are setting in.

The container shipping industry remained strongly under pressure during the first quarter of 2021. The drop in demand that is usually seen at the end of the Chinese New Year has not happened this year. Transport prices have therefore remained at high levels.

In March, the grounding of the container ship "Ever Given", which blocked the Suez Canal for 6 days and immobilized 450 ships, further aggravated the disruption of the market, with a general desynchronization of services, delayed delivery, a lack of empty containers available and congestion at destination ports.

In terms of rates, prices are installed in a bullish tunnel.

The market is characterized by an increase, a situation that perfectly illustrates the inflationary pressures of the first trimester.

On the Asia-Europe corridor, the price increase reached + 10% for the quarter. Official data show a 199% increase in spot prices between the 1st quarter of 2020 and 2021!

Prices remain high, not only under the effect of the capacity control policy put in place by shipping companies to protect their operating margins but also because the demand for maritime transport is expanding.

UPDATE April, 26th, 2021:

As indicated in the previous newsletter and market outlook below, some domino effects are having a huge impact on the sea freight market, worldwide:

- the blockage of the Suez Canal in March

- the lack of equipment

- the congestion of American and now European ports.

The main difficulties encountered are:

1. Longer transit times

Ships navigate between 11 and 12 knots, which is half their regular commercial speed.

Transit times are extended from 12 to 17 days at the port of destination.

This slowdown is due to congestion in European ports.

In order not to arrive at the port when there is no more room at the quay, the shipping companies are choosing to slow them down.

The arrival time is therefore unreliable and forecasts are difficult to obtain.

2. Ships’ unloading times

Vessels’ unloading time is 30-50% longer than it used to be.

Several factors lead to a longer unloading time:

- Large volumes to unload

- Less availability of teams in ports.

- A shortage of drivers, especially in the USA.

3. Equipment availability and pricing

The various attempts by the sea freight companies to increase the number of equipment have so far failed.

The situation even tends to worsen and finding empty containers within 2 to 3 weeks is almost impossible.

The spaces and equipment are already in use for the entire month of April and May.

The most attractive freight rates are now being rejected when booking and prevent carriers from securing the space and equipment needed for future departures.

As far as future sea freight rates are concerned, shipping companies do not commit beyond 15 days and the rates announced for the second half of April are already at the level of January 2021.

In addition, shipping companies are announcing “blank sailing” in China for weeks 16, 17, 19, and 21 and for the Indian Sub-Continent for weeks 16 and 18.

For the months of May and June, the traditional public holidays are also to be taken into consideration:

- Public holidays in France (May 1, 8, 13, and 21)

- And in China (Labor Day from May 3 to 5, and the Dragon Boat Festival from June 12 to 14)

UPDATE April, 9th, 2021:

With a worldwide vaccine distribution effort underway, the global pandemic still impacting most regions of the world, and supply chain disruptions persisting, the transportation environment remained unpredictable as we move into 2021.

These uncertainties may continue at least through the first half of the year, with shippers feeling the impacts across most modes.

Regardless of the specific model, the warehousing and distribution environment appears to be a common issue for many freight operators right now.

This persistent labor shortage—particularly for warehousing and distribution—combined with social distancing requirements is slowing supply chain and logistics activities.

The disruptions caused by the pandemic will have a “lasting impact” on the ocean shipping industry, where shipping delays and container shortages are becoming more common.

The recent blockage of the Suez Canal is the latest incident in a long chain of events that contributes to the disruption of the maritime market and disrupts the entire logistics chain.

Despite the redeployment of capacities by the shipping companies as well as the investment and negotiations between carriers and port handling companies, the coming weeks and months will be marked by:

• An absence of optimal visibility on the arrivals and departures of ships: risk of goods left at the dock for extended periods, the impossibility of bringing in a container on the agreed day

• Even greater ship delays, leading to massive congestion in ports.

• A significant risk of cancellations of stopovers in the absence of exceptional and rapid measures on the handling of ships, and the extension of the working hours of handlers and carriers

• The unloading of containers at ports not provided for on the bills of lading, aimed at optimizing rotations and minimizing the major risks of bottlenecks (example: unloading of containers consigned in Fos at the port of Hamburg, additional transportation costs)

• Continuity of the difficulties of lack of space on board and available equipment

• Maintaining or even increasing freight rates on the Asia-Europe trade lane (ceiling observed for a few days may increase due to lack of capacity)

• The implementation of PSS sees an increase in rates on other axes, in particular on the Transatlantic axis

• The establishment of new surcharges linked to congestion or shortages of space or equipment

The airfreight capacity currently remains at about 57% of the total market (including freighters) and about 18% less than what it was in early March 2020.

That - in itself - creates issues and problems for shippers and importers

********************

UPDATE March, 26th, 2021:

SUEZ CANAL

Please be kindly advised that all traffic at the Suez Canal continues to remain blocked as local authorities struggled to free the 224,000-ton container ship blockade at one of the world’s most vital shipping routes, particularly for the oil, and gas, and chemical sectors.

Over the past 72 hours, cargo ship MV Ever Given has made only minor changes to its position despite efforts to drag it to deeper water and amid a low tide overnight that has slowed efforts to dislodge the massive container ship.

The Suez Canal blockade could further exacerbate excessive congestion at European ports if the cargo were to arrive all at once, as well as persisting container shortages in Asia that have led to surging freight rates, should the situation continue to worsen.

The Suez Canal blockage has already had immeasurable impacts on global shipping routes and the passage of goods.

Around 185 vessels have already been affected — mostly bulk carriers, container ships, and oil or chemical tankers — that were stranded at the Suez Canal waiting to cross.

A rough estimate of the economic impacts suggests that the blockage could potentially result in losses of up to USD 400 million (EUR 338.2 million) an hour, with westbound traffic worth around USD 5.1 billion (EUR 4.3 billion) a day and eastbound traffic at approximately USD 4.5 billion (EUR 3.8 billion).

The Suez Canal blockade could further exacerbate excessive congestion at European ports if the cargo were to arrive all at once, as well as persisting container shortages in Asia that have led to surging freight rates, should the situation continue to worsen.

If the situation were to continue to prevail, it could have an outsized impact and create bottlenecks at European ports as soon as next week, while at the same time risking delays for the return of desperately needed containers in China.

The stopovers planned for ships will for some be canceled.

Sea Freight companies are already considering a new tax to offset the costs resulting from this expectation.

As I write this message, no one can tell how long it is going to take to dislodge the cargo ship, and how long it is going to take to unblock the long line of waiting vessels, the sea freight companies have chosen not to re-route their vessels via South of Africa and has decided to line up instead.

TURKEY:

The second wave of C-19 is still affecting the freight market negatively.

For road freight, the requirement for PCR tests for drivers has been discontinued.

The supply-demand between the EU and Turkey is still unbalanced but improving compared to February.

There are still passenger flight cancellations to some EU countries.

For sea freight, equipment shortages continue and rates are still high.

Due to the geographic location of Turkey compared to the Far East, EU market demand increased especially for medical textile products (masks, gowns, etc.).

Turkey to Europe export volume has also increased.

Truck procurement and management costs also increased.

Compared to January, the Euro was more stable in February and this has been reflected in an increase in import demand in Turkey.

PORT SITUATION IN THE USA (WEST COAST):

There are currently 26 ships (-5 from March 1st) at anchor out of which 24 are container vessels awaiting berths in LAX/LGB.

All terminals continue to suffer from severe congestion due to the spike in import volumes.

Currently 19 ships (+6) are at anchor or drifting in the San Francisco Bay area.

Berth congestion continues to worsen with ships waiting up to 7 shifts at anchorage

***********************

UPDATE MARCH, 3rd, 2021:

AIRFREIGHT MARKET:

The air cargo market is becoming more volatile as hopes fade for the return of belly holds.

Hopes for a recovery in belly-hold airfreight capacity to relieve the tight lift situation are fading as passenger traffic suffers setbacks from the Covid-19 pandemic.

According to the TAC Index, the average freight rate between Shanghai and Northern Europe climbed by 8% last week (home stretch before Chinese New Year).

Compared to the same period last year, it is up 88%.

SEA FREIGHT MARKET:

The overall outlook is that demand remains strong also in Q2 and for the rest of the year; besides, there is no indication of major changes on the capacity side => and capacity will not increase much on these trades.

The blank sailings are continuing, which are solely for schedule recovery purposes due to huge vessel delays through port congestions and bad weather.

It has been estimated that the world needs the equivalent of 500,000 more TEUs (roughly enough to fill 25 of the largest ships in operation) to satisfy the current demand.

In the meantime, standard container rates on transpacific routes are quadruple what they were a year ago.

And that is before equipment surcharges and premiums for guaranteed loading are added.

SITUATION IN GERMANY:

Following a decision made on February 11th, the lockdown in Germany has been extended until 7 March 21.

Since February 4th, border controls are in place with the Czech Republic, Slovakia, and the Austrian province of Tyrol, as those countries/regions are considered virus-variant areas.

There are exceptions to entry for health personnel, lorry drivers, and other transport personnel in goods traffic, provided a negative test is not older than 48 hours.

PORT SITUATION IN THE USA (WEST COAST):

TURKEY:

The second wave of C-19 is still affecting the freight market negatively.

For road freight, the requirement for PCR tests for drivers has been discontinued.

The supply-demand between the EU and Turkey is still unbalanced but improving compared to February.

There are still passenger flight cancellations to some EU countries.

For sea freight, equipment shortages continue and rates are still high.

Due to the geographic location of Turkey compared to the Far East, EU market demand increased especially for medical textile products (masks, gowns, etc.).

Turkey to Europe export volume has also increased.

Truck procurement and management costs also increased.

Compared to January, the Euro was more stable in February and this has been reflected in an increase in import demand in Turkey.

**********************************************

UPDATE FEBRUARY, 5TH, 2021:

AIRFREIGHT MARKET:

Airfreight rates are expected to remain elevated in 2021 as the demand outlook remains uncertain and belly capacity is slowly re-introduced into the market.

There is a strong increase in PPE traffic out of China and Southeast Asia, fueled by new preventative measures in the US and EU and the start of the vaccination programs.

A faster than expected rise in e-commerce demand, Covid-19 vaccine supply chains, and PPE demand would all drive the airfreight market over the coming year.

SEA FREIGHT MARKET:

Over the last few months, the container shipping sector has experienced major supply chain issues due to a box shortage in Asia, a surge in demand, and port congestions.

The squeeze on space and record ocean freight rates on the Asia-Europe trade lane is showing no sign of abating in the run-up to Chinese New Year (CNY), with further rate hikes now expected later this month and the real prices paid by customers soaring to unprecedented levels.

The average spot price had jumped some 2,000% over the past five years.

Meanwhile, as shippers grapple with rising freight rates, service levels from carriers appear to be heading in the opposite direction.

Global container service scheduled reliability has declined to its lowest levels since records began.

The latest schedule reliability data for December shows just 44.6% of vessels arriving on time, which means that for the fifth consecutive month, global schedule reliability has been the lowest across all months since 2011.

Source: Geodis

SITUATION IN TURKEY

The serious equipment shortage and vessel space problems of the last 2-3 months are expected to continue at least until the end of April.

Almost no imports are arriving in Turkey, therefore there is no available equipment for exports from Turkey.

Everything possible is being done to secure equipment but on some routes, bookings cannot be accepted until the end of March.

CURRENT SITUATION IN THE USA

Figures show that prices from China to the US West coast are up by around 180% year on year; to the East coast, there is a 103% jump on last year.

****************************************************

UPDATE JANUARY 15th 2021:

AIRFREIGHT MARKET:

Airfreight rates are expected to remain elevated in 2021 as the demand outlook remains uncertain and belly capacity is slowly re-introduced into the market.

On the demand front, a faster than expected rise in e-commerce demand, Covid-19 vaccine supply chains, and PPE demand will all drive the airfreight market over the coming year.

Last year, airfreight rates on major east-west trade lanes ended at a very high level.

Data from TAC Index show that - in December - average prices from Hong Kong to North America were up 107.2% year on year.

From Hong Kong to Europe average rates increased 77.5% compared with a year earlier. And from Europe to North America there was a 184.1% increase.

SEA FREIGHT MARKET:

Record Asia-Europe ocean freight rates rise further.

The squeeze on space and record ocean freight rates on the Asia-Europe trade lane is showing no sign of abating in the run-up to Chinese New Year (CNY), with further rate hikes now expected later this month and the real prices paid by customers soaring to unprecedented levels.

Spot rates from Asia to Europe spiked again last week on equipment shortages, port delays, and lack of capacity ahead of CNY factory closures in Asia from mid-February.

Shanghai-Rotterdam rates jumped 34% last week, up 282% compared to a year earlier.

Spot freight rates on the Shanghai-Genoa lanes meanwhile gained 18% last week, up 212% compared to a year earlier.

Shippers warned to prepare for bunker surcharge increase

Shippers were spared the worst impacts of the introduction of new low-sulfur fuel regulations last year due to a collapse in the price of oil following the outbreak of the coronavirus pandemic.

But as the economic recovery continues and demand for oil returns alongside cuts by major oil-producing countries such as Saudi Arabia, bunker prices are on the rise again.

After a dramatic fall in March and April that brought down the price of both heavy fuel oil and very low sulfur fuel oil, bunker prices increased and stabilized at a level of around $290 per ton for IFO380 and around $340 per ton for VLSFO.

RAIL FREIGHT MARKET:

In January, there is close to zero new departure plan of shipments from westbound China to Europe due to a shortage of container equipment. Demand for space on westbound service is extremely high. Eastbound service from Europe to China is running with a reduced frequency which caused very tight capacity in the market as well.

This situation will not change before the Chinese New Year.

CURRENT SITUATIONS IN THE USA

US forwarders struggle with ‘Insane’ pre-Chinese New Year ocean buildup

Transpacific head haul rates and demand overheat ahead of next month’s Chinese New Year holidays, with carriers failing to honor contracts and guaranteed slots only available at prices far higher than listed spot rates.

Transpacific ocean freight markets are showing no sign of cooling down as supply chain bottlenecks, equipment shortages, and a lack of capacity keep ocean logistics capacity tight and prices high.

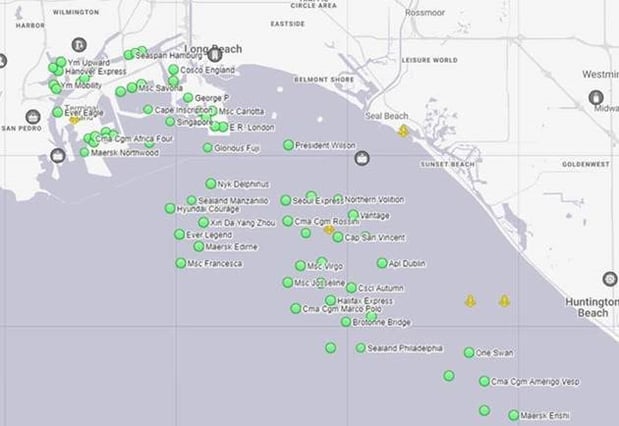

Below is a picture of Long Beach port showing a long line of vessels waiting to offload containers

TURKEY:

A curfew during weekday evenings and the weekend continues.

As far as the supply chain is concerned, the most important issues are equipment & vessel space.

This is also affecting freight rates.

Rates are increasing and bookings need to be placed 2-3 weeks in advance at least.

*****************************************************************************

UPDATE JANUARY 9TH 2021:

SEA FREIGHT MARKET:

A look back at 2020, the year that container supply chains collapsed: the intervention of Chinese regulators in September dampened the rise in transpacific rates – albeit that spot rates to the US west coast remain some 180% higher than a year ago – but not elsewhere; for example, rates to Europe are currently 260% higher and to the South American east coast 220% higher than a year ago.

The unintended consequence of piling on more capacity to meet the export boom from Asia was to throw carriers’ equipment balances totally out of kilter as containers got stuck on ships awaiting berths, on quays awaiting transport, or log-jammed at other intermodal pinch points.

But container spot rates as recorded by the Shanghai Containerized Freight Index (SCFI) are not representative of the actual price paid by embattled shippers who, desperate to secure space and equipment, face a myriad of surcharges and premium fees.

Some freight forwarders were obliged to charter their own ships from China to Denmark to cover their commitments to customers.

This unprecedented action by the forwarders must be seen as a warning to carriers that whatever lies ahead in 2021, container lines need to return to the days of offering an acceptable level of service at fair rate levels or risk further proactive measures by their customers.

The situation in the USA:

The Marine Exchange of Southern California reported 24 container ships at anchor in San Pedro Bay on Monday.

Five more were due to arrive and four were due to leave anchorage for berths at the ports of Los Angeles or Long Beach.

The Marine Exchange reported that regular anchorages are full and several of the contingency anchorages are also occupied.

Marine traffic map using ship positioning data reveals the extent of the container-ship pileup in San Pedro Bay.

The situation has not improved over recent weeks — if anything, it appears to have worsened.

Persistent port and rail ramp congestion, container chassis shortages, and excessive detention and demurrage fees from carriers, as well as upheaval among air cargo service providers, are causing significant harm to your import and export supply chains.

U.S. customs brokers, freight forwarders, and non-vessel-operating common carriers (NVOCCs) of all sizes are facing multi-week delays and higher costs of routing shipments through the nation's congested seaports, airports, and rail ramps.

The frustration of these delays is compounded by the imposition of excessive detention and demurrage fees by ocean carriers.

In the worst cases, containers are being reported lost by the carriers and terminals.

The same types of delays to commerce are experienced at the nation's airports.

Truckers hired to retrieve or deliver freight encounter inefficiencies at ports and airports that severely disrupt and add significant cost to what should be an efficient activity.

In many areas, there is a severe shortage of available truckers to move your cargo domestically.

TURKEY:

Flight frequencies have been decreased and air freight rates are at a high level. On the general sea freight export and import side, demand has not increased but as both equipment & vessel space supplies are very low, it's difficult to find available sailings in time to meet everyone’s schedules

****************************************************************************

UPDATE DECEMBER 28TH 2020:

Tight capacity has been a characteristic of both the air and sea freight forwarding markets in 2020.

Container shipping alliances were able to work together and cut capacity during the pandemic, keeping rates at high levels.

Although likely not to the same extent, this trend could continue in the years ahead, pushing some shippers to consider other modal options, such as rail or sea air.

AIRFREIGHT MARKET

From Hong Kong to Europe, rates in November increased by 43.1% a month earlier and initial figures seem to indicate they will continue to grow in December and January.

An increase in pricing at this time of year isn’t too much of a surprise as the peak season starts and various shopping promotions take place.

However, prices remain far above last year’s levels as a result of the lack of overall air cargo capacity due to the grounding of many passenger services.

Average rates from Hong Kong to North America are up 91.9% a year ago, while to Europe they are 65% up.

OCEAN FREIGHT MARKET

Asia-Europe ocean freight spot rates have risen to new record levels, reflecting high demand, capacity bottlenecks, and a shortage of empty containers and other equipment.

Figures from the Shanghai Containerized Freight Index (SCFI) show average rates from Shanghai to northern Europe rising by almost a quarter in just one week to a new record, up 24% compared with the previous week – when prices had already seen a rise of more than 13% on the previous week’s levels.

That takes Asia-Europe rates to more than double their level this time last month. And rate rises in the Asia-Mediterranean trade were even larger, a rise of almost 30% (28.9%) in the week.

Rate rises from China overall were more moderate, although average spot prices to Europe from ten hub ports in China, as measured by the China Containerized Freight Index (CCFI), rose by more than 15%, week on week. Meanwhile, average prices from China to the US remained broadly stable for another week, as they have for several weeks.

The situation in the USA

The United States has seen a surge of imports from Asia coming into the ports on the West Coast.

The increase in volumes, along with labor and chassis shortages have contributed to ongoing, unprecedented congestion and backlogs.

The congestion is now being felt at air and seaports across the U.S., due to compounding factors.

While we are currently in peak season, there was also a backlog of freight from around the world due to the coronavirus situation.

Along with the extra freight coming in, personnel shortages are occurring more frequently due to the possibility of virus exposure and social distancing measures are in place at the terminals and trans-loading facilities.

All of these factors have combined to create days- and sometimes weeks-long terminal dwell times.

Airport Situation

At Chicago’s O’Hare, New York’s JFK, New Jersey’s Newark, as well as Los Angeles’ LAX and other major airports around the country, some cargo retrievals are delayed for over a week due to the increased quantities of cargo flying into the airports.

Ocean Port Situation

The Ports of Los Angeles/Long Beach, as well as the Port of New Jersey, are suffering the worst delays in the United States currently as the Trans-Pacific Eastbound lane is seeing record levels of demand.

Covid 19 vaccine impact on Supply Chains and WW transportation:

As pharmaceutical companies around the world race to develop and distribute COVID-19 vaccines, logistics providers are preparing to build the supply chain needed to deliver these drugs to billions of people as rapidly as possible.

Once a vaccine is approved, manufactured at scale, and ready for distribution, the high-stakes supply chain will require additional logistics capacity and specialized equipment, as well as cold-storage facilities and processing capabilities by ground handlers. The timing of the start of the distribution efforts is particularly critical as shipment capacity – notably for air freight, which is likely to serve as the main mode of transportation for the vaccines – remains 20-25 percent lower than in the same period of 2019 due to unavailable belly cargo on passenger flights. As of November 2020, air cargo rates remained up to 60 percent higher year-on-year on some major trade lanes, with the year-end holiday season likely to push up rates even further in the coming weeks.

Particular concerns revolve around the impact the global distribution efforts could have on air cargo capacity and rate levels on the three major air cargo trade lanes between Asia, Europe, and North America as well as on secondary trade lanes.

This report lays out a detailed overview of the various challenges as they relate to logistics capacity, airport cargo handling, and congestion.

COVID-19 VACCINE

Logistic Outlook