You’re working on a product with a substantial electronic content and you’re planning for it to go into volume production ? Unless you have specialist facilities yourself, you’re probably thinking about using the services of a contract electronics manufacturer (CEM). But how do you go about choosing the right one, and what do you need to do to work successfully with them? Read on to discover our 5 tips for successful volume production.

At Asteelflash - USI we understand that your supply chain is at the heart of your business and we work hard to make it easy for you to keep it in good shape.

Discover 4 tips to successfully manufacture with us

Start early

Choosing your CEM should be one of the first steps in your project, long before your design is finalised. That way you can call on your CEM’s expertise during the design process. The CEM’s engineers may well be able to advise you about ways to enhance your design so that your product is easier and less costly to manufacture and test. If you wait until your design is finished before you talk to a CEM, it may be too late to incorporate these desirable changes.

Look for a partner

Choose a CEM that will work with you as a partner, not just a supplier. In every project, there are inevitably bumps along the way – you need a CEM that will work with you to iron out those bumps efficiently, effectively and economically. You also want a CEM that you can get to know so you work together well not only on this project but also on future projects.

Check capabilities and capacity

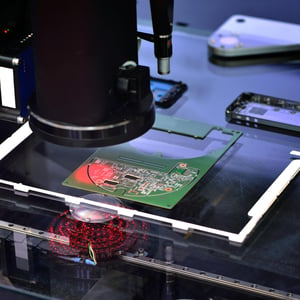

Can the CEM you’re considering provide the complete service you want? This may include not only PCB assembly but also component sourcing, provision of enclosures, final product assembly, testing and even design support. Does the CEM have the equipment needed to work efficiently with the components you’re using? And are they the right size to suit the number of products you expect to produce each year?

Consider global reach

Does the CEM have a global presence? You may think this doesn’t matter, but a CEM with a global organisation can choose the most competitive location for manufacturing your products, and for minimising shipping costs. And a global CEM will have global contacts for sourcing components – a big advantage at times of component shortages.

Trust your CEM

When you’ve chosen the right CEM, following the guidance we’ve just given, trust their advice. Remember that they have had experience of producing thousands of different products for thousands of customers. They will know the problems and pitfalls that could limit the success of your product and they will know what to do to put things right. Listen carefully to what they tell you – their advice is invaluable.

| Follow these five tips and your new product will be well on the way to success, but you can make life even easier for yourself – when you’re looking for a CEM partner, you can save time and effort by contacting Asteelflash first! We meet all the criteria listed here and, thanks to our new partnership with USI, a world leader in electronic design and manufacturing services, we can support you in every stage of taking your product from concept to volume production. |

Find out more about what a CEM can do for you, the questions to ask before manufacturing your product and the advantages of using an external partner, by downloading our free and informative ‘Electronic Manufacturing Services Guide’.