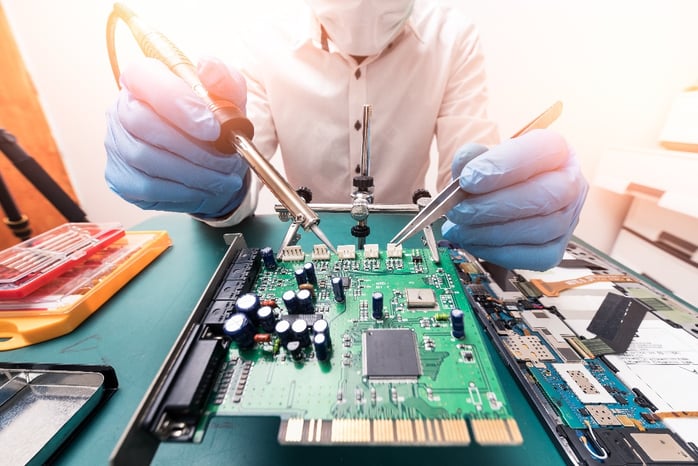

To succeed in your business, you must have an efficient supply chain. If your job is to design and sell electronic products, you have certainly faced challenges with the procurement of electronic components. Fortunately, there is a solution to improve your supply chain: choosing the right EMS. In this article, we will explain how a good EMS partner can facilitate all of your supply chain needs.

The advantages of choosing the right EMS

Choosing an EMS to design and manufacture a PCBA has many advantages. Here are the main ones:

- Knowledge of the market : like an electronic designer knows its products, it is the role of the EMS company to know the global electronic market trends. In fact, an EMS has many customers with various requests, and the sum of all these experiences makes it a leading expert. An EMS knows what works or what doesn’t. They can offer the right solutions immediately, and avoid problematic suppliers and faulty components.

- Quality and Inventory Management Policy : an EMS follows an inventory policy in order to maximize the customer’s satisfaction and minimize the costs. An EMS is a professional for components sourcing that follows inventory procedures and prevents any possible sourcing issues, thanks to the use of dedicated software like “SiliconExpert”. With an EMS, the supply chain is also transparent, optimized by mathematical models and sometimes by Artificial Intelligence.

- Materials requirement planning system (MRP) : MRP system enables an EMS company to establish a requirements schedule and forecasts automatically for each product. Advanced manufacturing software can integrate multi-level Bill of Materials (BOM) and take everything into account: the current production schedule, parts to be purchased and lead times, so as to predict any issue. Furthermore, an EMS supplier always makes sure that the components of your BOM cover the entire lifetime of your product.

Top criteria to have in mind when selecting a new EMS partner

The above arguments showed the main advantages of an EMS supplier from a supply chain standpoint.

Here are three top criteria that will help you choose the perfect EMS partner.

1. The global footprint of the EMS

At the design stage of a product, the customer of an EMS probably knows where its main market is, but they rarely know the full potential of this market on a worldwide scale. That’s why it’s best to work with an EMS supplier who has a global presence from the beginning.

Consider the following example: a company that manufactures smartphones in China to sell in Asia wants to establish in the US market. To avoid customs duty and stay competitive, it will be necessary to move the production to a plant on the American continent.

2. A Harmonized Global Company

To ensure the highest repeatability and reproducibility of a product, a global EMS company must be harmonized. Machines, IT systems, ERP, project management and quality department must be the same in every entity of the company to ensure a smooth transfer of the production from one manufacturing site to another.

3. A Presence in All Economic Sectors

In a fast-paced components market context, choosing an EMS that works in every market segment may allow you to benefit from the best knowledge available. In some cases, it’s possible to transfer solutions and processes from one sector to another. If the customer can’t find where the issue comes from, an EMS supplier with a multisector approach will know where to pick up the perfect technical solutions since they have probably already experienced it before. For example, in robotics, many technologies such as ultrasonic sensors come from the automotive industry.

To conclude

An EMS appears to be a partner of choice to manufacture electronic products because market knowledge, Quality control procedures, and planning systems, are part of its daily routine. A top-tier EMS company has a global footprint, a harmonized system, and a presence in every economic sector. With years of experience, an Electronic Manufacturing Services supplier has faced and solved many issues on numerous different products, has implemented new harmonized processes and built large quantities of products. EMS companies are definitely a key advantage to any OEM who wants to build products of quality at the best costs.